Woolwich Polytechnic School

Bauder Total Roof System (BTRS) with Euroglaze rooflights

Synopsis

Situated in Thamesmead in London, Woolwich Polytechnic School is one of the largest boys’ secondary schools in the country. Having moved to the site in the late 1990’s, the school has since undergone several extensive renovations with the additions of three separate buildings, the Humanities block, the English and Art block and a dedicated Sixth Form block. However, being the oldest part of the school, the main building of Woolwich Polytechnic School was now ageing, therefore the school decided to request a roof survey on its degrading roof which included examining all aspects of the roof to find problematic areas in order to propose the right waterproofing solution to meet the needs of the building, free of charge.

Woolwich Polytechnic School

Woolwich Polytechnic School

Woolwich Polytechnic School

Bauder Building Board

|

Project:

|

Woolwich Polytechnic School

|

|

Location:

|

London

|

|

Project Type:

|

Refurbishment

|

|

Roof Area:

|

5400m²

|

|

Specifier:

|

Barker Associates

|

|

Approved Contractor:

|

R T Roofing Services Ltd

|

The specification

Bauder roof surveys provide precise technical data to determine the true condition of your roof and allows Bauder to create a bespoke specification for the recommended solution. Bauder provides two different roof survey techniques; core sampling and moisture mapping.

Roof survey’s include:

- Analysing the current roof covering and investigating the deck structure.

- Consideration of insulation upgrades to achieve required U-values.

- Consideration of drainage effectiveness and falls.

- Detailing of all roof penetrations and connecting interfaces.

- Implications of any additional weight loading.

- Wind uplift calculations and required fixing methods and restraint.

- Recommending the correct course of action and remedial measures necessary.

- Impartially specifying the right waterproofing system to meet building needs and budget.

- Recommending our best suited approved contractors to install the replacement waterproofing on your project.

- Outlining the guarantee ensuring it meets project expectations.

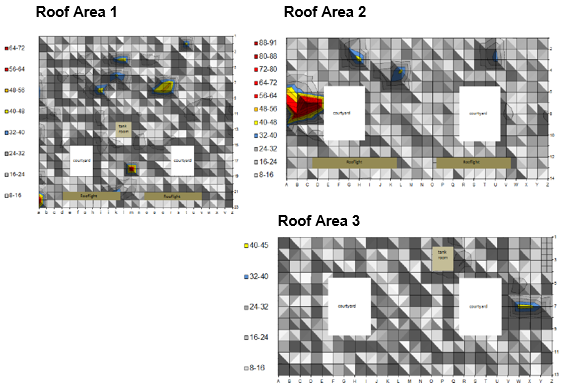

Bauder’s area technical manager was commissioned to carry out an in-depth moisture mapping roof survey to three roof areas within the main roof with a total area of 5400m² using a Troxler 3216 Roof Reader. Moisture mapping scientifically verified the specific levels and locations of moisture within the existing waterproofing and identified the true condition of the roof which was then plotted, and a visual data report produced to determine the remedial action needed. The survey concluded that the existing single ply insulated waterproofing system contained water to several areas with the addition of there also being some localised small areas of water within the existing original build-up. This was estimated to be in the region of 30-40% on the first roof section and 25-35% on the second. The third section of roof contained water to one localised area.

After completing the roof survey, Bauder was able to recommend that only the upper roof system required stripping, and with some minimal repair, the original roof could be left insitu and overlaid in the usual manner with an upgrade of insulation to comply with the current Part L building regulations, which was cost-effective and shortened the project time.

It was determined that the Bauder Total Roof System (BTRS) would be the best solution to refurbish the school roof. BTRS is a first class bituminous system in terms of both quality and technology. It is robust and durable enough to withstand foot traffic along with most permanantley sited plant and is specified in applications where outstanding longevity is required, making it the perfect system for Woolwich Polytechnic School.

Bauder’s Euroglaze rooflights were also specified after the roof survey showed the existing rooflights did not comply with current safety regulations and were showing signs of damage and aging. It was also noted that the existing rooflights were single layer glazed and offered little in the way of thermal performance. Measurements were taken during the site survey to ensure a correct fit. Bauder Euroglaze is the most advanced rooflight design available that maximises on current technology. With high standards of illumination, insulation and ventilation to satisfy the requirements of the latest Building Regulations.

The result

Approved contractor R T Roofing Services carried out the minor repairs before installing Bauder products to the 5400m² roof areas. Following a succession of site visits by Bauder’s expert site technicians and a final leak test, it was deemed that a high standard of workmanship had been achieved throughout installation and a 20-year product, workmanship and design guarantee was issued to the client.

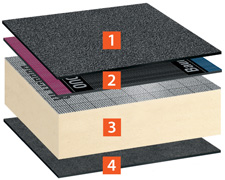

System installed

Bauder Total Roof System (BTRS)

After Woolwich Polytechnic School’s previous waterproofing system failing, the client was keen to use a system they could be sure would last. BTRS is Bauder’s heavy duty, robust and extremely tough bituminous system available with a service life in excess of 35 years as stated in BBA Certificate 10/4744, which made it the perfect system for the project.

|

1 Bauder K5K

|

A top quality, heavy duty, torch-applied SBS elastomeric bitumen capping sheet which features a spunbond polyester reinforcement to allow the finished product to cope with structural movement without fracture, and a mineral finish to provide protection against UV degradation.

|

|

2 BauderTEC KSA DUO

|

A technically advanced self-adhesive SBS elastomeric bitumen underlayer with “DUO” lap technology to ensure thorough sealing of lap joints, even in lower temperatures. The product was used on the project because of its cleaner, safer and faster installation benefits compared to traditional torch-applied membranes.

|

|

3 BauderPIR FA-TE

|

A rigid urethane foam insulation faced on both sides with aluminium foil chosen to provide a lightweight, thermal insulation for the project which was 80mm in depth to meet the required U- value.

|

|

4 Bauder Super AL-E

|

A thick, robust, torch-applied, elastomeric bitumen vapour barrier, featuring a tear resistant aluminium foil lining for vapour impermeability. This was specifically chosen on this project for these qualities as the system was being installed over an old single ply waterproofing system.

|